By considering and managing these factors effectively, businesses can work towards reducing conversion cost, increasing profitability, and achieving business objectives. It’s essential to continuously monitor and analyze these factors to adapt to market changes and stay competitive in the ever-evolving business environment. For example, choosing a prefabricated fiberglass or acrylic shower pan and shower surround will significantly lower your costs.

- Prime costs are crucial for setting product prices and ensuring profitability because they represent the direct expenses of materials and labor needed to produce goods.

- In process costing systems, conversion costs are averaged across units produced, ensuring consistent cost allocation.

- By examining these factors, businesses can gain valuable insights into their cost structures and make informed decisions about pricing, budgeting, and investment in process improvements.

- If the company has a strategic focus on innovation and quality, maintaining in-house production might be the preferred choice, despite the higher per-unit cost.

- This guide explores the concept, components, importance, calculation methods, and strategies for managing conversion costs effectively.

- As a Colorado van conversion company that’s been building adventure-ready vans for nearly a decade, The Vansmith has converted hundreds of vans across every budget range imaginable.

Excluding Indirect Costs in Prime Cost Calculations

His mission is to provide high quality, durable solutions that fit conversion cost each customers needs. However, some areas of the construction are advanced and will require a great deal of skills and experience if performing on your own. While you might save on basic tasks, underestimating the difficulty of electrical work and plumbing installations can lead to costly (and potentially dangerous) mistakes.

- In a process costing system, where the production process is divided into several departments or stages, the cost of conversion is computed for each department separately.

- Remember that these components interact dynamically, and a holistic approach is essential for accurate conversion cost analysis.

- This includes rent, utilities, machine repairs, and any other expenses incurred within the factory.

- Understanding their nuances, allocating them accurately, and optimizing their impact are critical for sustainable business operations.

B. Production Efficiency

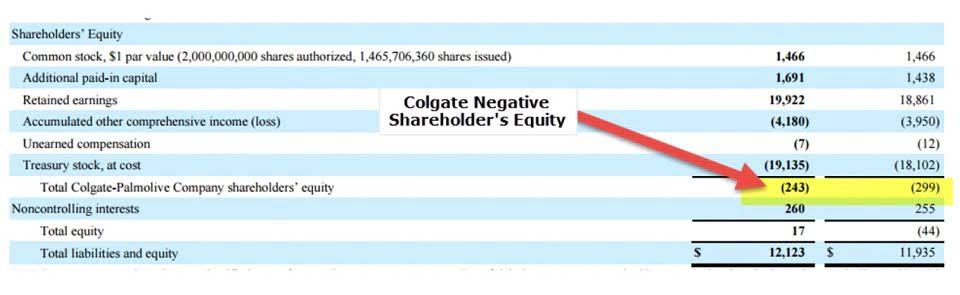

Conversion costs are important for cost accounting and management because they help to measure the efficiency and profitability of the production process. They also help to allocate the costs of goods sold (COGS) and inventory valuation. In the realm of cost accounting, conversion costs play a pivotal role in shaping the pricing strategies of products. These costs, which encompass both direct labor and manufacturing overheads, are integral to transforming raw materials into finished goods.

Direct Labor Costs

Conversion costs are not just a line item in accounting; they are a reflection of the company’s operational efficiency and strategic pricing decisions. They are the bridge between raw materials and finished products, and understanding their role is essential for any business aiming to succeed in a competitive marketplace. By carefully managing and analyzing these costs, businesses can make informed decisions that enhance their financial performance and market positioning. From the perspective of a factory floor manager, conversion costs are a daily reality.

Conversion cost What is Conversion Cost and How to Calculate It

The manufacturing sector analyses both prime costs and conversion costs to measure efficiency in the production of a product. Conversion cost is the cost incurred by any manufacturing entity in converting its raw material into finished goods capable of being sold in the market. It usually includes the total value of labor cost and other applied overheads like factory overheads, administrative overheads, etc.

A Comparative Analysis

Furthermore, testing and experimentation allow businesses to evaluate the impact of overhead costs on the profitability of marketing campaigns. Companies can identify areas of their marketing campaign where costs can be reduced without negatively impacting conversion rates. This optimization can be done by analyzing the data and identifying cost-effective marketing channels and strategies.

A. Conversion Cost Formula

The work requires a high level of skill, and it’s easy to make mistakes that could lead to a poor aesthetic and even a higher risk of water damage and mold issues. It’s a good idea to hire a pro for this bathroom renovation project, and you’ll usually need to, anyway, if the conversion includes changes to your plumbing. A tub-to-shower conversion can be a great way to modernize your bathroom, but there are some cases in which you may want to reconsider. Most importantly, if you’re converting your only bathtub to a shower, you could devalue your home. Additionally, if you have a low window above your tub, converting to a shower will require reframing and replacing the window for safety and privacy, which can significantly increase your costs. Your selection of shower features will also have an impact on the overall cost of the shower remodel project.

Why is Conversion Cost important?

- The direct material cost of the chair will include $5 paid to the assembly worker and $2 paid to the paint and polish worker.

- Upon completion, earn a prestigious certificate to bolster your resume and career prospects.

- Analyzing trends in these costs may reveal issues such as low worker productivity, equipment downtime, or wasteful processes.

- These nuanced adjustments, tailored to the specific stages of the funnel, can lead to a significant reduction in conversion costs.

- This is because they are both required to complete the production of that specific item.

One of the key factors to consider when optimizing landing pages is the analysis of conversion costs. This involves examining the various expenses incurred during the conversion process, such as overhead costs, advertising expenses, and per-unit pricing. By identifying and analyzing these QuickBooks costs, businesses can better understand their conversion funnel and make informed decisions to improve efficiency and maximize their return on investment.

Module 1: Nature of Managerial Accounting

At the higher end, let’s examine a recent Family XL Plus build that sold for $130,000 (including the van). This demonstrates what’s possible when budget allows for premium features and family-specific needs. Let’s start with examples that prove you can get van life-ready at various budget levels.

Typically, it is equal to the sum of entity’s total direct labor cost and total manufacturing overhead cost. Conversion costs include the direct labor and overhead expenses incurred as raw materials are transformed into finished products. To calculate the prime cost of a bicycle, all its direct material and direct labor Partnership Accounting expenses must be aggregated.